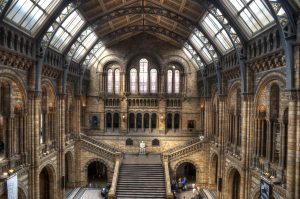

Natural History Museum

Client: AtkinsRéalis & DBR Limited

Location: South Kensington, London, UK

Helifix InSkew Warm Roof Fixings provide an engineered fixing solution for securing the new timber battens on the warm roof upgrade of London’s iconic Natural History Museum.

Sitting between the Science Museum and the Victoria and Albert Museum in South Kensington’s Exhibition Row, the Natural History Museum is home to some 80 million individual exhibits, including the famous 80 foot suspended Blue Whale skeleton and the pigeons studied by Charles Darwin, that informed his works on ‘The Origin of the Species’.

Opened in 1881, the landmark building is currently undergoing a £multi-million upgrade and renewal project designed to improve environmental performance and provide enhanced display space. As part of the project, the original Waterhouse slate and lead pitched roofs to the three original galleries, which were nearing the end of their expected life, are being replaced with added insulation, to improve the building’s energy efficiency and provide a more stable environment for its priceless exhibits.

The Challenge

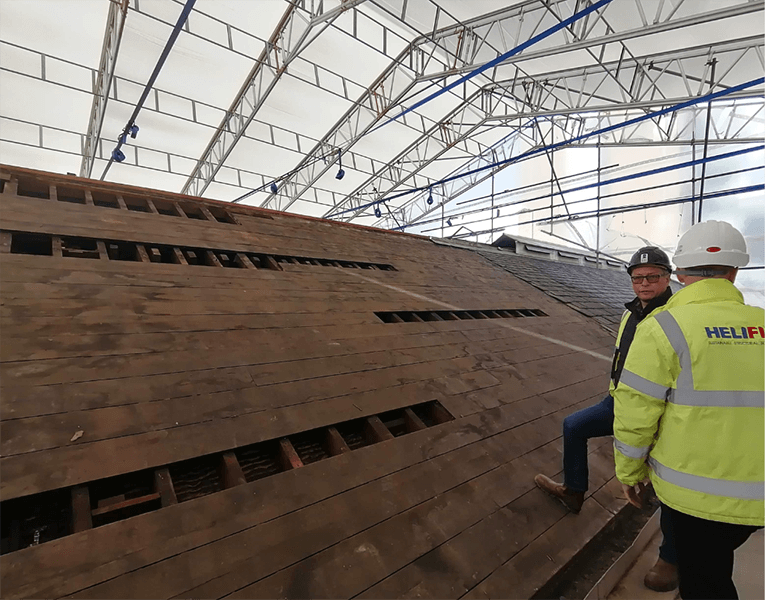

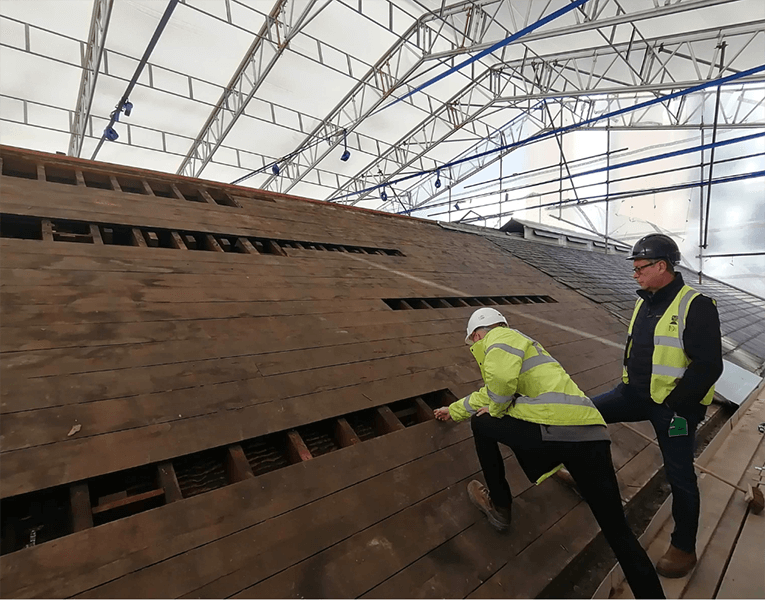

To meet the demanding upgrade in thermal efficiency required, whilst preserving Waterhouse’s original visual for the Heritage listed building, architects and heritage surveyors, AtkinsRéalis, and building restoration specialists, DBR London, created a unique insulated warm roof specification. Their design incorporated a thick, 105mm, rigid insulation slab and substantial sarking layer, fixed through timber counter battens to the original roof pine rafters and topped with either lead or very heavy, 90kg/m2, slate tiles to achieve the closest possible match to the original Waterhouse specification.

The exceptional weight and deep profile of the 70/30o dual pitch structure, coupled with variations in batten depth, created a challenge in securing the roof’s counter battens into the rafters in order to provide structural support against the wind and sliding loads.

The solution

As traditional nails or screws could not provide a sufficient solution to address the complex issues, Atkins approached Leviat’s Technical Team for Helifix solutions to provide a suitable option. After a thorough investigation, a design was put together using the Helifix InSkew Warm Roof Fixings which comprehensively tackled the challenges that arose from the desired warm roof design.

Specially designed for fixing pitched warm roof constructions, the unique helical profile of the InSkew fixing ensures a permanent fixture, providing the required support for wind sand sliding loads, and avoids splitting to battens. In addition, it’s relatively small cross-sectional area, and no head design, minimises cold bridging across the structure to ensure optimum thermal performance.

Leviat was able to demonstrate the Helifix solution using an on-site mock-up of the roof, as a result of which approximately 10,000 of the 205mm long Super 6 InSkew fixings, in 304 grade stainless steel, were fixed throughout the 300m2 roof area.

Leviat design and installation specialists provided technical support throughout the project, including on-site training to demonstrate correct and safe installation procedures to the DBR operatives, who were able to fix the InSkew fixings quickly and easily using a power driver attachment fitted to a standard (SDS) hammer drill.

Helifix at the Natural History Museum - Helifix UK

Helifix Inspecting at the Natural History Museum - Helifix UK

You may also be interested in

Find an Approved Installer

Helifix’s Approved Installers ensure customers can be confident that repairs are carried out using the latest techniques to obtain an efficient, reliable, cost-effective solution.

FIND AN APPROVED INSTALLER