Helifix Movement Joints

Helifix Movement Joints

Helifix Movement Joints

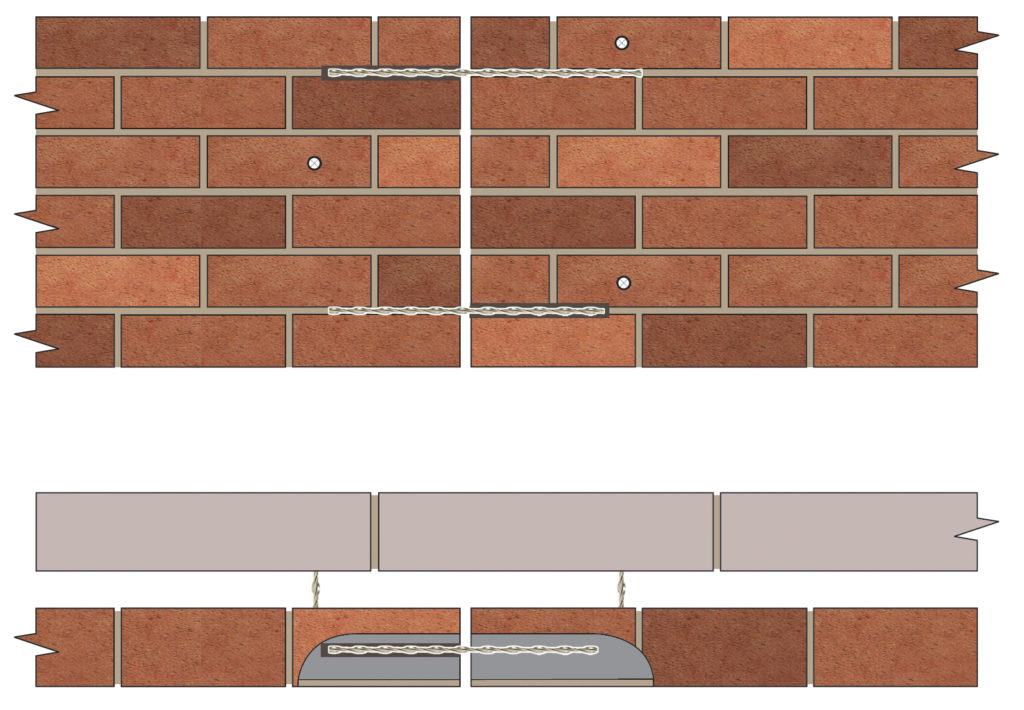

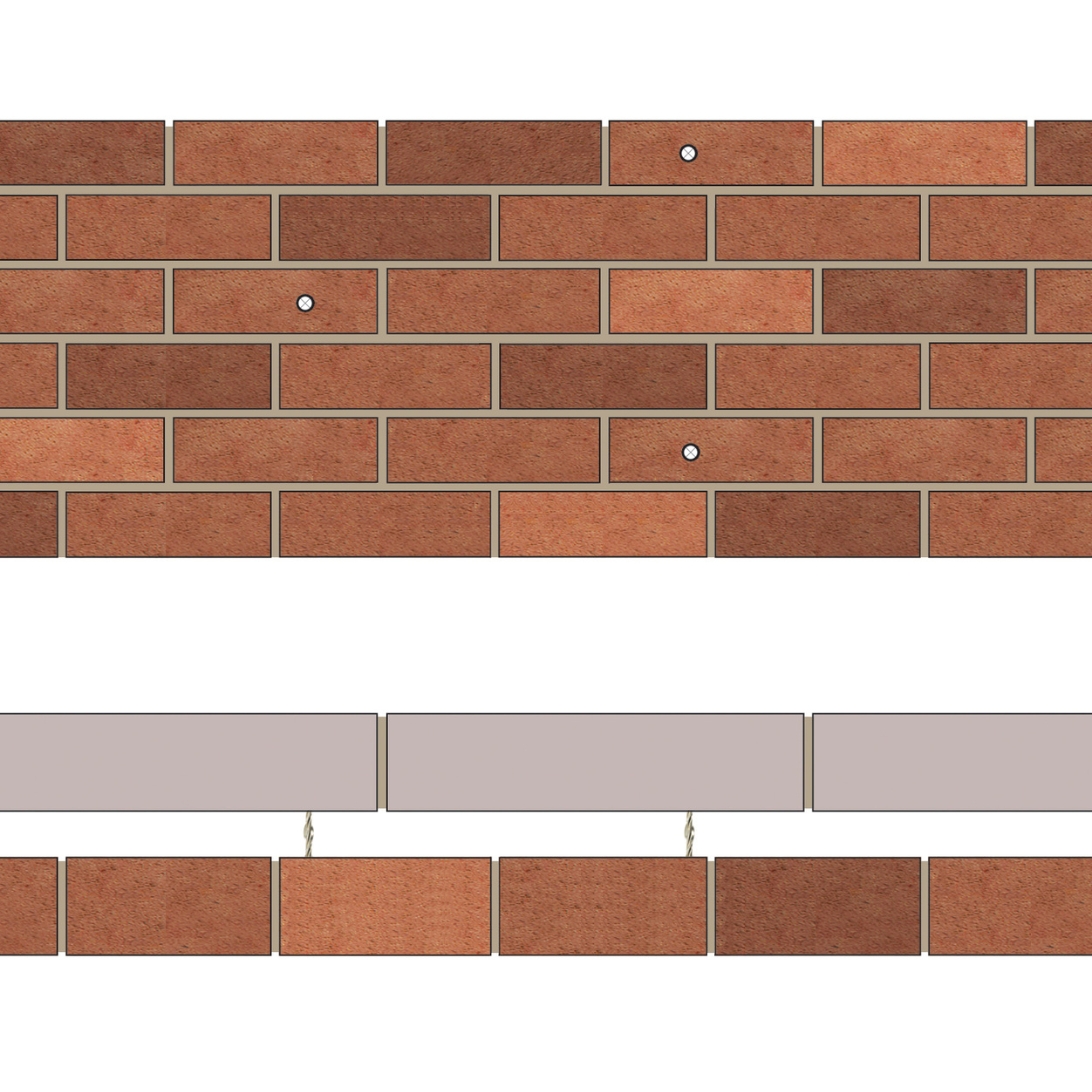

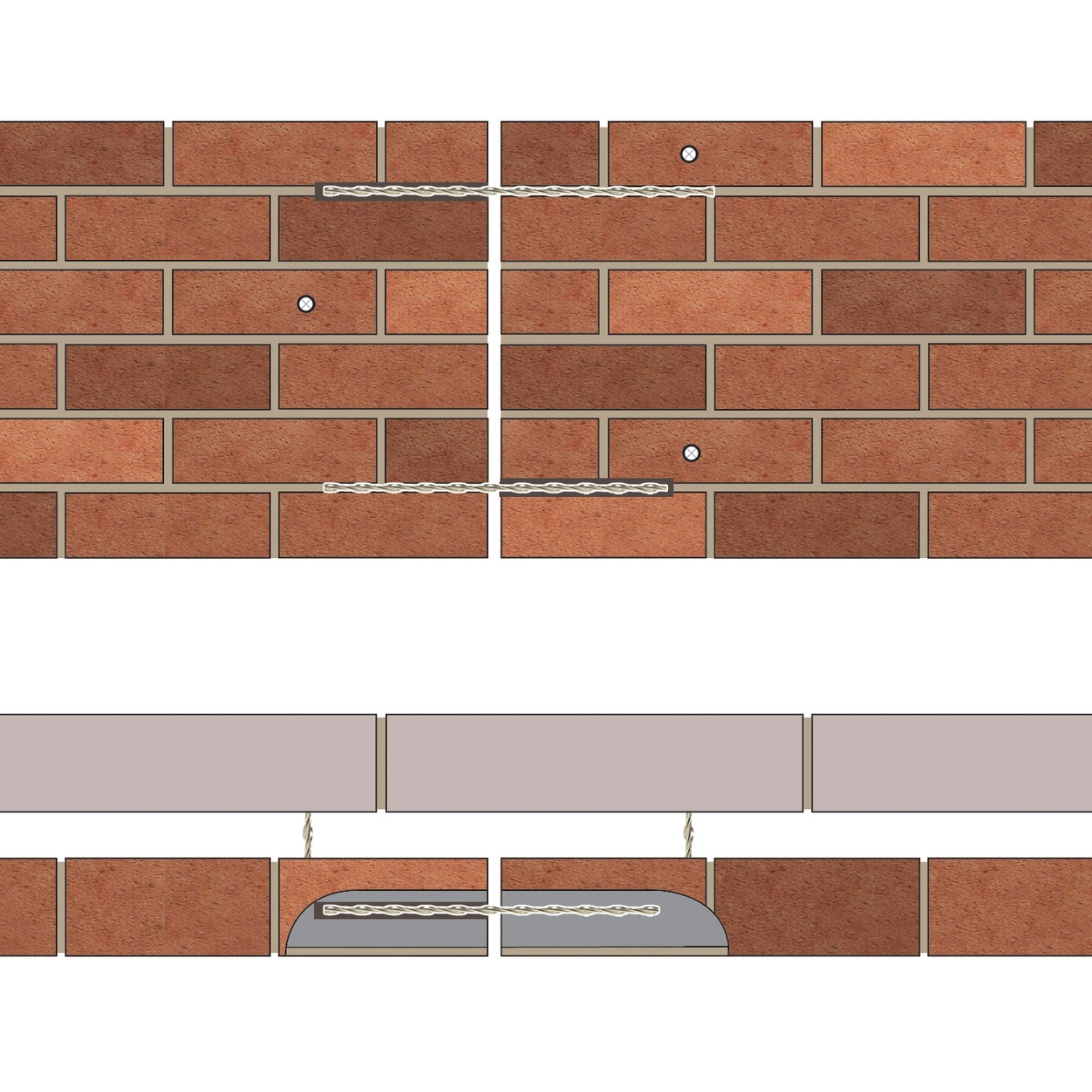

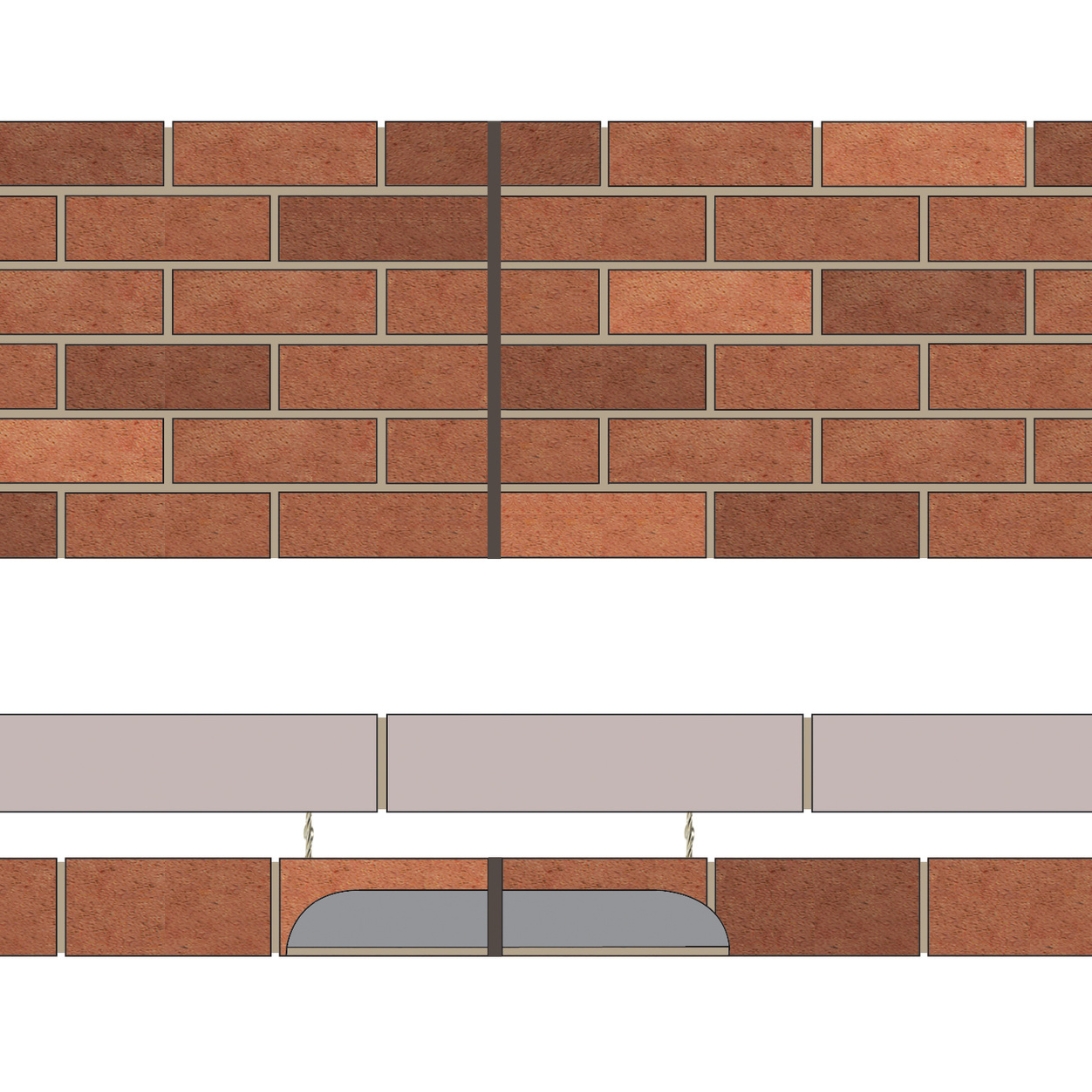

Helifix HeliBar stainless steel helical bars in conjunction with plastic debonding sleeves can be used to create a movement joint in an existing wall.

The Helifix HeliBar restrains the masonry against lateral loads whilst the sleeve allows the masonry to expand and contract.

Send a product enquiryHelifix HeliBar stainless steel helical bars in conjunction with plastic debonding sleeves can be used to create a movement joint in an existing wall.

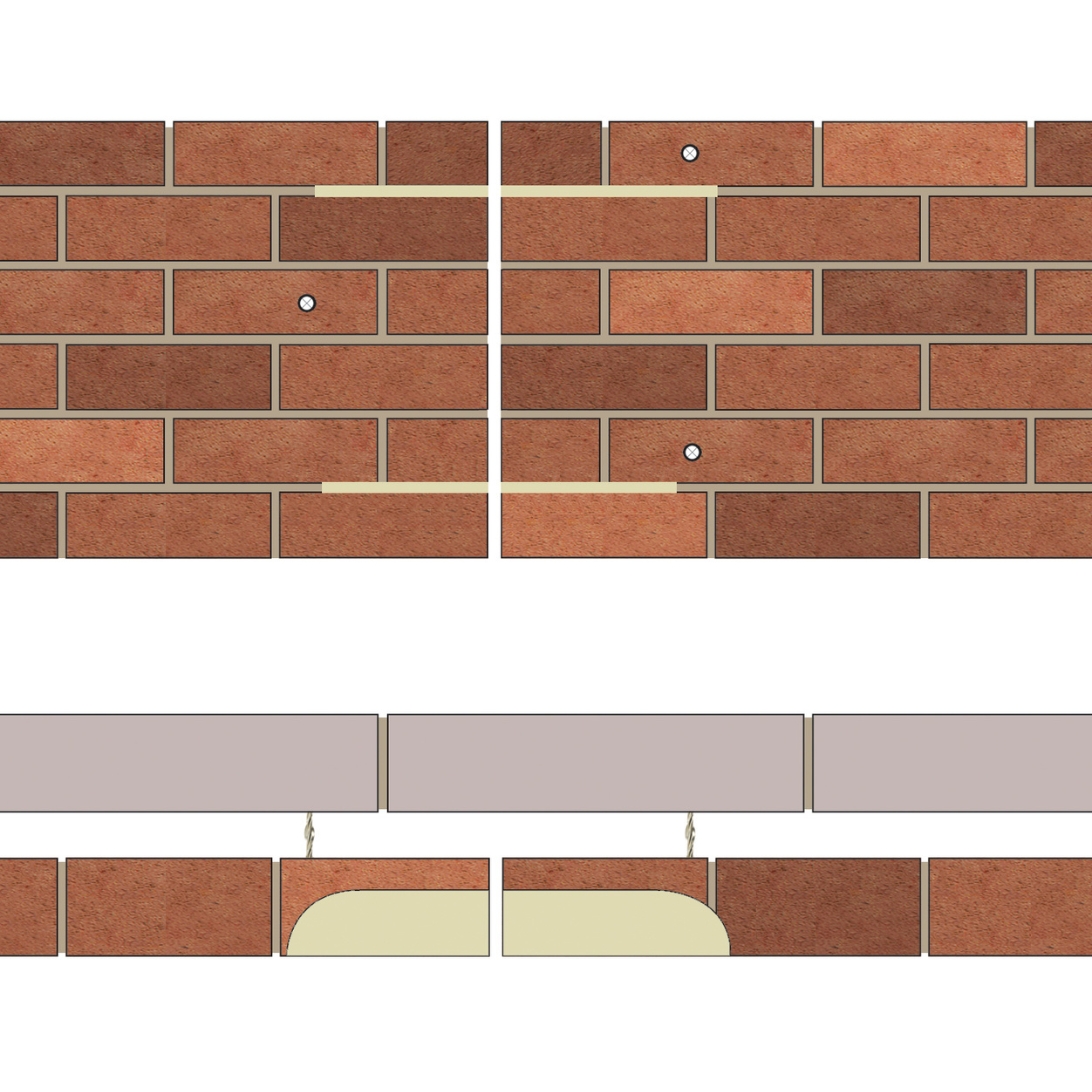

The 6mm diameter Helifix HeliBar is available in either austenitic stainless steel Grade 304 (1.4301) or 316 (1.4401) and is supplied in a standard length of 400mm for this application. The sleeve is 200mm long to debond half the bar, allowing movement to take place at the joint.

The Helifix HeliBar restrains the masonry against lateral loads whilst the sleeve allows the masonry to expand and contract.

The Helifix HeliBar-sleeve assembly is installed in cut slots which cross the location of the new movement joint, with the sleeve part positioned on alternate left and right sides of the bar.

Installation

Enquire Now

Mandatory Fields*

Find an Approved Installer

Helifix’s Approved Installers ensure customers can be confident that repairs are carried out using the latest techniques to obtain an efficient, reliable, cost-effective solution.

Find an approved installer