In post-war Britain, the urgent need for new housing drove innovation in construction, with local authorities encouraged by government to build new housing quickly and efficiently. One of the most widely adopted methods during this period was the use of Large Panel Systems (LPS), prefabricated concrete panels that enabled rapid construction of high-rise housing blocks across the country. While a building constructed using LPS was seen as a modern solution to the housing shortage in the 1960s, many decades later, a legacy of structural and safety concerns has emerged. With many of these buildings still in use, identifying effective and practical remediation strategies is more important than ever.

In 1968, a gas explosion at Ronan Point, a new 22-storey tower block built using LPS in east London, led to a devastating partial collapse. The tragedy exposed the fundamental vulnerability of LPS construction and its reliance on panel joints rather than the panels themselves for structural stability. Ronan Point became a stark warning of the potential for disproportionate collapse, when a small failure can cascade into a catastrophic structural event.

Understanding LPS construction

In order to full address the challenges these buildings represent, it’s essential to understand how they were originally constructed. Large Panel System (LPS) buildings are typically constructed using precast reinforced concrete panels, including floor slabs and wall panels that extend the full height of a storey. The factory-produced panels were generally strong but the effectiveness of connections between panels was dependent on dimension tolerance, particularly the matching of tie bar locations in different elements. Any localised structural defect, due to ageing, poor workmanship or a localised explosion, can result in a collective, progressive failure that compromises the entire structural system.

Today, it is estimated that around 575 LPS tower blocks¹ remain occupied across the UK. Many are now showing signs of ageing, deterioration and design shortcomings that were never intended to support a building’s lifespan beyond a few decades. Over the years, concerns have grown around their structural resilience, especially in the absence of comprehensive maintenance records. Many LPS buildings were constructed with limited mechanical ties between floors and load-bearing walls, making them particularly dependent on the integrity of the connections between prefabricated units. Unfortunately, these joints can degrade over time, leaving the entire structure more susceptible to movement or failure under stress.

Fire safety is another major concern. LPS buildings often lack adequate compartmentation, with gaps between panels and insufficient fire-stopping measures in place. In some cases, the concrete cover over reinforcement is inadequate, making these buildings vulnerable to fire and corrosion. These risks are compounded by poor documentation with decades-old records often incomplete or missing altogether, making it difficult for owners and engineers to assess the true condition of the structure without invasive inspections.²

Building Safety Act

A new era of regulation is now driving the reassessment of LPS buildings across the UK. The Building Safety Act 2022 introduced stronger requirements for the structural assessment of higher-risk residential buildings (HRBs) with a particular focus on fire resistance and overall structural integrity. Under this new legislation, building owners are now responsible for ensuring their properties are safe and compliant. The establishment of the Building Safety Regulator underscores the importance of regular inspections, transparent reporting, and remedial action where necessary. While this blog only touches briefly on the regulatory angle, it’s clear that the bar for structural safety has been significantly raised.

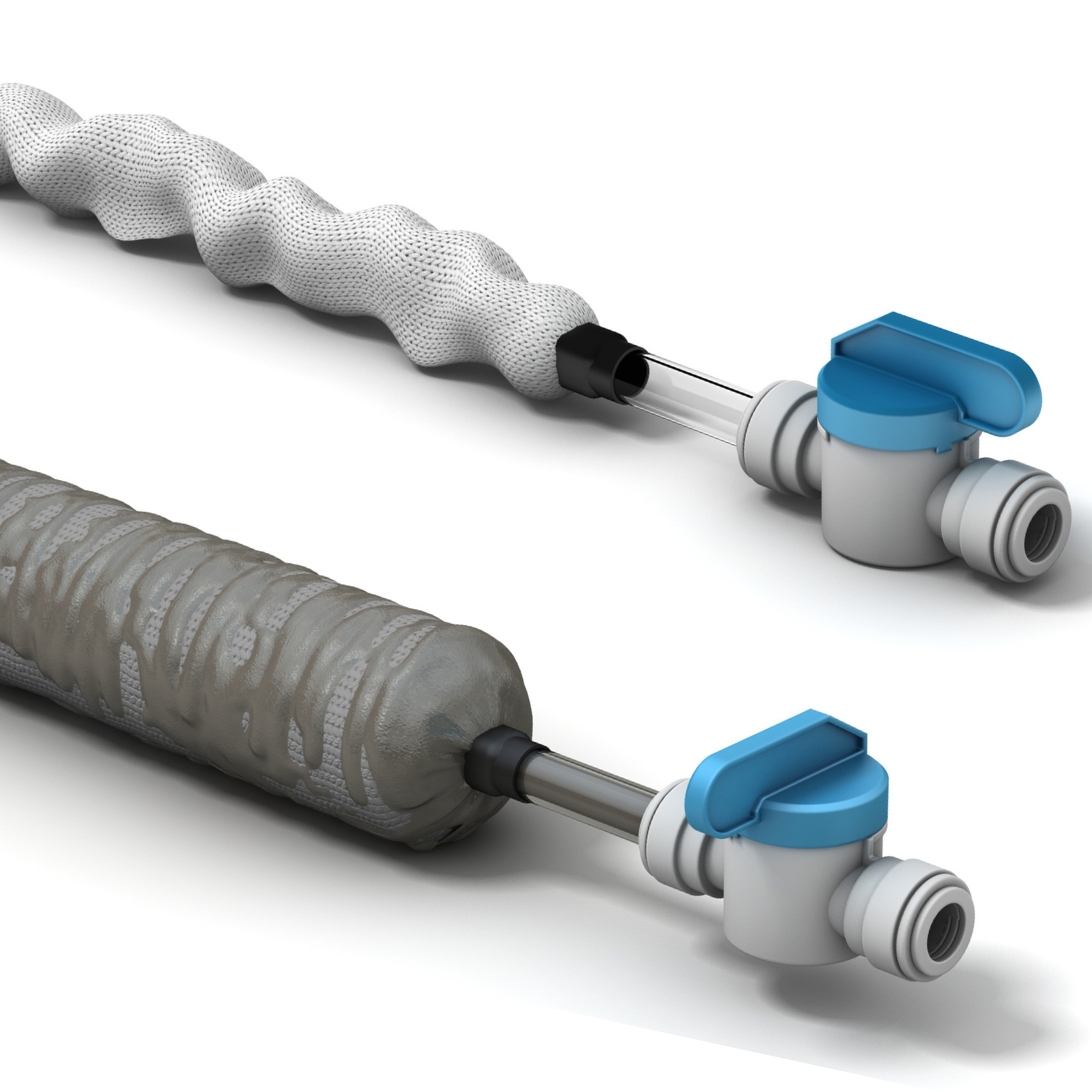

In light of these challenges, effective and minimally disruptive retrofit solutions are in high demand. This is where Leviat provides a vital service, offering a range of remedial anchoring systems designed to enhance the stability of existing structures, including those constructed with LPS. Among the most versatile and long-lasting solutions is Leviat’s Helifix SockFix system, a fully grouted stainless-steel anchor installed into pre-drilled holes within the concrete structure. The system includes a woven sock that expands when filled with grout, forming a secure, load-bearing bond with the surrounding substrate.

Helifix SockFix installed into a floor

Helifix SockFix HDA before and after inflation

Addressing the risk

This method is particularly well-suited for LPS buildings, where enhancing the mechanical connection between concrete panels and their supporting elements is crucial. By inserting Helifix SockFix anchors into key locations, engineers can effectively tie together disconnected or weakened parts of the structure. This improves structural integrity, increases resistance to accidental loads such as explosions or impacts, and reduces the likelihood of localised failures propagating throughout the building.

A specific challenge in many LPS buildings is fixing into lightweight hollow precast floor slabs, making it difficult to achieve reliable anchorage using conventional methods. The Helifix SockFix system overcomes this issue by forming a secure load-bearing bond within the available substrate. Once fixed into these slabs, the anchors are then tested onsite to ensure each fixing can safely perform.

One of the advantages of the SockFix system is that it can be installed with minimal disruption to residents and without significant alterations to the building’s appearance, an important consideration in occupied, heritage or conservation-sensitive developments.

Proof Testing of Helfix SockFix installed in LPS Projects

Installation of Helifix SockFix

Leviat’s Helifix solutions are not only practical but also adaptable. Each installation is designed around the specific challenges of the building in question, ensuring that the remedial work addresses real-world conditions rather than relying on outdated drawings or assumptions. This tailored approach provides peace of mind for building owners, surveyors and residents alike.

The continuing presence of LPS buildings across the UK makes it essential to address these historic construction challenges proactively. With modern understanding of structural behaviour and improved materials technology, the risks posed by outdated design and ageing infrastructure can be significantly mitigated. Through targeted assessments and smart intervention, it’s possible to extend the safe lifespan of these buildings while meeting today’s rigorous safety considerations.

Leviat’s Helifix anchoring solutions provide an effective way to reinforce and stabilise LPS buildings, supporting long-term performance and compliance with evolving safety standards. With the construction sector continuing to grapple with the legacy of post-war construction, Leviat combines technical expertise with innovative anchoring systems which can play an important role in ensuring these structures remain safe, resilient and ready for the future.

To find out more about Leviat’s Helifix anchoring and repair solutions, email sales.helifix.uk@leviat.com or call +44 (0)20 8735 5200

² https://www.istructe.org/resources/guidance/assessing-higher-risk-buildings-under-the-building/