Helifix Micro-Piles

Helifix Micro-Piles

Helifix Micro-Piles

Efficient, economical and non-disruptive method of foundation stabilisation

The Helifix Dixie pipe piles system provides structural support to a building’s foundations following subsidence.

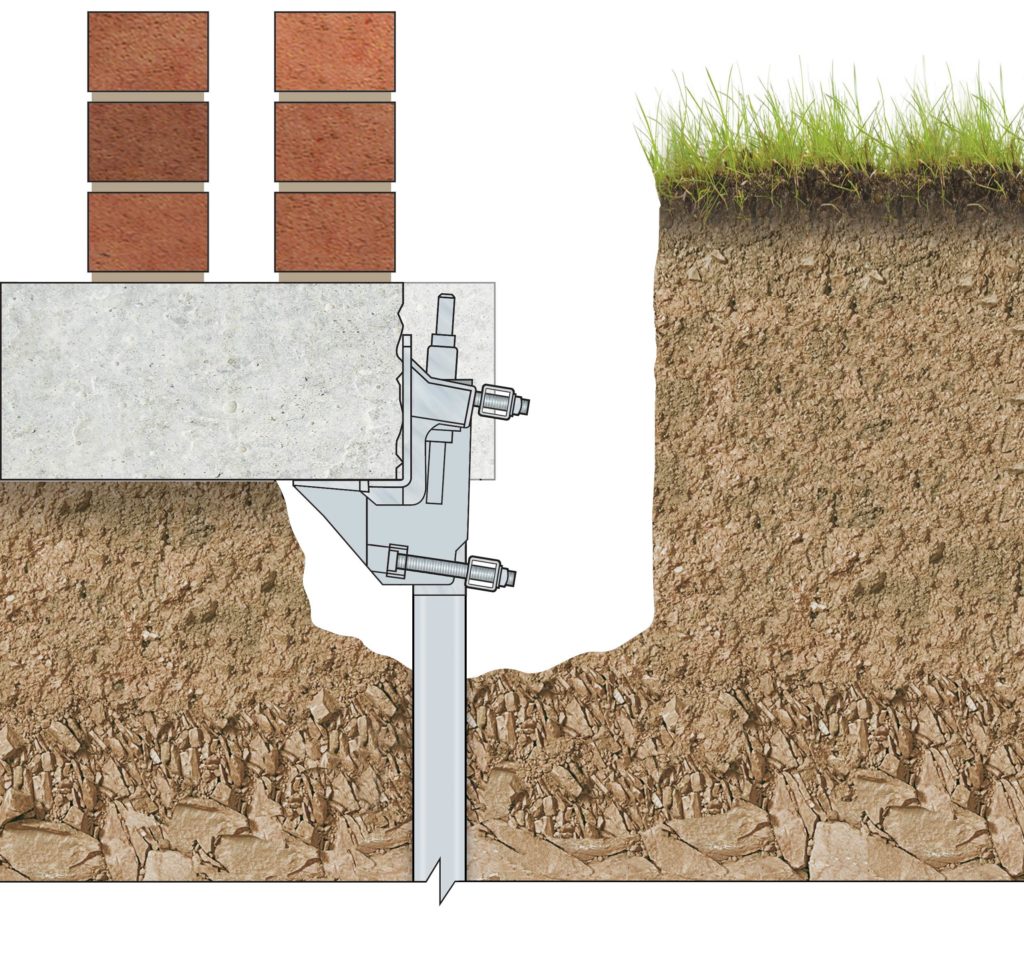

Send a product enquiryThe Helifix Dixie pipe piles system provides structural support to a building’s foundations following subsidence. This efficient and economical method of foundation stabilisation is ideal for situations with restricted access and screws into virtually any soil type. Minimal disruption is caused by micro-piles to the building fabric or to the occupants who normally remain in the residence while work is carried out.

The Helifix Dixie piled foundation system can also be used to support new permanent and temporary buildings. Piled foundations are typically more cost effective than traditional foundations requiring deep excavations, when load-bearing strata is at a deeper level. More information is available on our applications page.

Leviat in-house engineers assess each situation and design repairs based on the damage and weight of the individual property and the local ground conditions. Fully trained contractors supply and install the systems.

System Components

This fully engineered remedial solution consists of 3 components:

- Helical Lead Section

- Extension Piece

- Bracket Assembly

Load Bearing Capacity

The load bearing capacity of a helical pile is dependent on:

- The strength of the soil – evaluated using standard techniques.

- The projected area of the helical plates – plate surface area and number.

- Depth of the plates below ground surface level.

Helical piles should be installed to an estimated depth based on soil investigations to ensure the best load bearing capacity.

The soil behaviour mechanism is assumed to follow the theory that the overall capacity of the helical pile is equal to the sum of the capacity of the individual plates. Any friction contribution along the central shaft is generally ignored. The helical plates are spaced far enough apart to avoid overlapping of individual “pressure bulbs” to obtain the best performance.

The following is Terzaghi’s general bearing capacity equation to determine the ultimate capacity of the soil.

Qult=Ah (cNc+q’Nq+0.5γ’BNγ)

Where:

Qult – ultimate capacity of the soil, kN

Ah – projected plate area, m²

c – soil cohesion, kN/m²

q’ – effective overburden pressure, kN/m²

B – footing width (base width), m

γ’ – effective unit weight of the soil, kN/m³

Nc, Nq & Nγ – bearing capacity factors

Pile Spacing

Having determined the capacity of the helical pile, it is recommended that the centre-to-centre spacing between adjacent piles be no less than five times the diameter of the largest plate.

Safety Factor

Once the ultimate capacity of the helical pile has been determined an appropriate safety factor must be applied, generally a minimum of 2, to give an acceptable working capacity. The appropriate level to be determined by the design engineer.

Installation

Product Enquiry

Mandatory Fields*

Find an Approved Installer

Helifix’s Approved Installers ensure customers can be confident that repairs are carried out using the latest techniques to obtain an efficient, reliable, cost-effective solution.

Find an approved installer